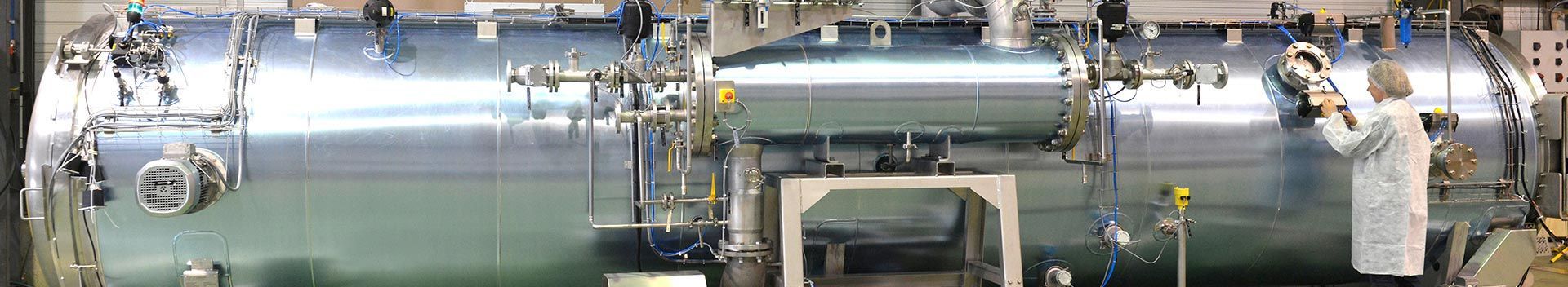

STERIFLOW Static

Quality, Reliability and Simplicity of maintenance

In this type of STERIFLOW Static, the water, discharged throughout the whole cycle, does not cause movements of the stainless steel baskets, which can contain such products as flacons, pouches, syringes, ampoules, etc.

Due to its high level of mechanical reliability and homogeneity of thermal processing, STERIFLOW appears to be one of the most widely used industrial processes of sterilization.

Steriflow Static for the discharge of superheated water

Each cycle takes place automatically, in conformity with the saved parameters, including highly accurate control of air back-pressure regardless of the temperature.

Water is sprayed over the products to be treated with great intensity. The hydraulic circuit of water in S* takes place as follows: pumping, Platular® exchange, douching arrangement, water flow over the products, douching and filtration arrangement, pumping.

STERIFLOW water flow system allows the refrigeration of products, using sterile water.

This autoclave is perfectly adapted for < 105°C processes.

Technical specifications :

Standard sizes :

- 900 mm

- 1300 mm

- 1450 mm

- 1600 mm

- 1800 mm

- 2000 mm

- 2100 mm (the first of its kind in 1982)

- 2300 mm (the former in 1984)

- Capacity from 2 to 7 baskets (depending on diameter) and a mechanical system of charging/discharging.

Benefits

- Perfect reproducibility of the programmed cycles.

- Air back-pressure management regardless of the temperature.

- Minimal maintenance costs. In fact, there is just one moving item in the S*, which is the pump.

- Steriflow is designed in a way that maximally reduces the amount of liquid used in the process.

- Power:

Static Steriflow features a powerful pump which provides for short and homogeneous cycles. All the products placed inside the autoclave are treated equally, regardless their position, while the reduced duration of the cycles provides for increased efficiency.

- The door:

It is locked by an air-driven system, which keeps it blocked throughout the whole cycle. Conception remains identical, it opens in horizontal or vertical positions.

- MPI Expert:

Due to the GAMP high performance user friendly control panel the parameters are saved automatically. A complete solution that includes the control and registering as well as a digital synoptic. It complies with 21CFR part 11.

The types of products or packaging :

All types of packaging including :

- large pouches

- non-PVC pouches

- glass or plastic ampoules

- bottles

- glass bottles

Accessories

Baskets design depends on packaging :

We ensure package integrity by using adapted baskets according to our customers’ needs and temperature homogeneity inside the basket.