SHAKA® Shake your taste buds !

Shaka® is the latest member of the Steriflow family. This retort is particularly innovative, provides a large reduction in sterilization cycle times (5 to 10 times). This is due to its shaking process and his capacity to quickly raise the temperature. The time benefit is carried over to the quality of the product, it ensure optimal taste performance and nutritional value. Shaka® is a simple alternative to aseptic technology.

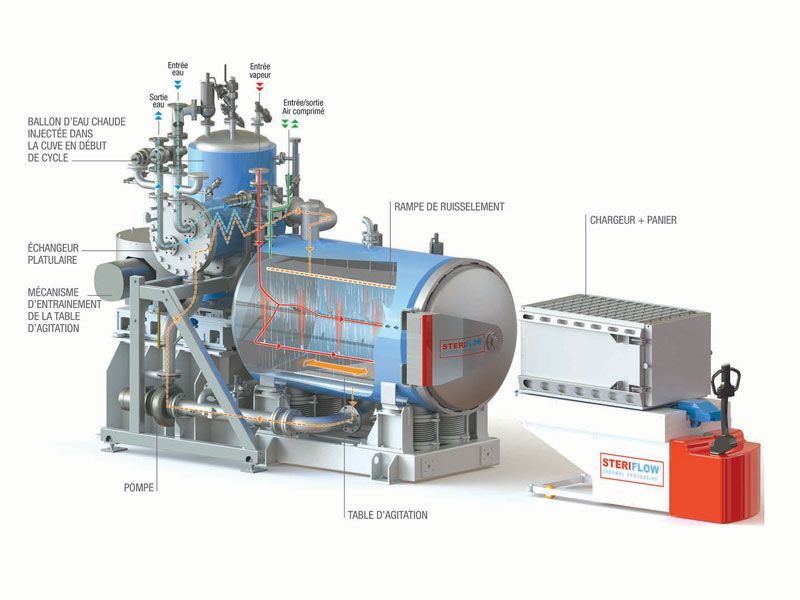

Cascading water Steriflow shaka®

Once the basket is locked into the Shaka®, the process involves three temperature stages : rising, holding temperature and final cooling.

You may select the shaking frequency as soon as the temperature rises. Preheated water and direct-steam humidification are used to reduce this Heating up phase. The cycle time is reduced 5 to 10 times by using high frequency shaking. This is resulting in radical changes of the heat transfer coefficient from the product. This type of retort also gives you the opportunity to run at higher than normal temperatures.

There is no overcooking, no loss of texture of the product. You get a coloured, high-quality product, which does not disintegrate and with an incomparable flavour due to the reduction in the cycle time. A significant difference compared to Static or Rotary retort.

During the entire cycle, shell internal pressure is regulated by injection or direct exhaust with two automatic valves controlled by the MPI.

An automatic handling system is needed for installation on several Shaka.

Technical specifications :

Standard sizes :

- 900 mm

- 1 300 mm

Radar level :

- In order to accurately control the volume of water at the cooling phase.

Temperature :

The sterilization temperature (sterilization value or FO) is defined by the manufacturer and will depend on the initial contamination of the product and its bacteriological characteristics.

Benefits :

- Healthier products, best preserved.

- A better conservation of vitamins and polyphenols.

- A decrease in the use of salt, preserve the taste and nutritional value of food.

- A more consistent texture, tests were carried out on delicate products such as courgette and Eggplant (see Figure).

- Cooling tempo for packagings is done with sterile water.

Types of packaging or products :

- Liquids such as sauces, soups…

- Viscous products (baby food…)

- Glass jar

Shaka Use Video : Industrial Shaker Sterilizer

Shaka® is a registered trademark of Zinetec UK Ltd