Our sterilization/pasteurization solutions for the pharmaceutical industry

For over 40 years, STERIFLOW has been providing scalable heat treatment solutions for the pharmaceutical industry. Our range of retort : superheated water, ventilated steam/air, saturated steam and Robustex, enables us to offer a broad base of solutions to our customers.

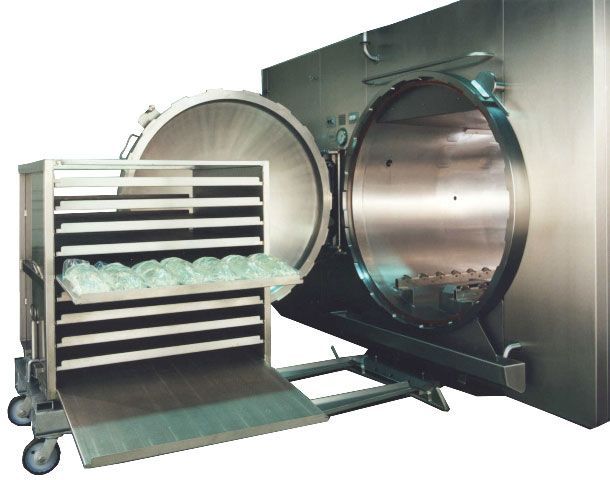

A wide range of autoclaves for sterilization/pasteurization of your pharmaceutical products

Depending on the product and packaging (glass bottle, PVC bags, PP pouch, syringe) according to product and heat treatment to be applied (sterilization, tyndallization…) our engineers will help you to select the most appropriate retort that suits your project. Our retort provide a wide variety of load volume from 90L (Robustex for NGOs) to more than 25m3.

Our solutions for the sterilization of your pharmaceutical products :

Streaming superheated water Autoclave

Ventilated air/vapor Autoclave

Saturated steam Autoclave

Robustex 90L for NGOs Autoclave