Cartography – Temperature distribution – Retort validation

We are regularly involved in assisting clients to carry out cartography on retorts with our own equipment.

What is autoclave temperature distribution?

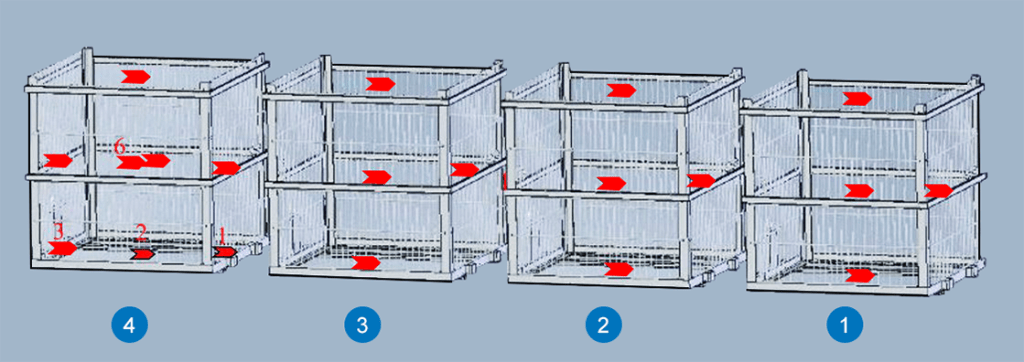

Autoclave mapping is an essential step in the sterilization process of products. It involves verifying the uniformity of temperature within the autoclave chamber during the sterilization cycle to ensure that all products receive the same amount of heat. This verification is particularly important in the case of significant changes related to heat treatment, such as acquiring a new autoclave, a new loading plan, or modifications to the parameters of the entering fluids.

Autoclave mapping aims to address several key questions, including:

- Where is the cold spot in the load?

- What is the temperature of the cold spot at the start of the plateau and during the plateau?

- How long does it take for the cold spot to reach the plateau temperature?

- Is the heat treatment uniform throughout the autoclave?

What are the advantages of autoclave mapping?

Optimization of heat treatment

Optimization of heat treatment

By verifying the heat distribution in the autoclave, mapping allows for the identification and elimination of potential cold spots. Therefore, the applied heat treatment is uniform across the entire product load. This temperature uniformity contributes to food safety and product quality.

Reduced risks of non-compliance

Reduced risks of non-compliance

Temperature uniformity reduces the risks of non-compliance associated with under-sterilized or, conversely, overcooked products, ensuring consistent product quality.

Mapping at Steriflow

At Steriflow, mapping procedures are conducted by our service engineers who follow specific protocols and have calibrated onboard temperature sensors.

Are you looking to optimize your sterilization cycles

and reduce costs and risks of non-compliance?

Our sales and technical teams are at your disposal for any inquiries.