STERIFLOW DALI

Low-frequency shaking, Rotary performance at advantageous prices…

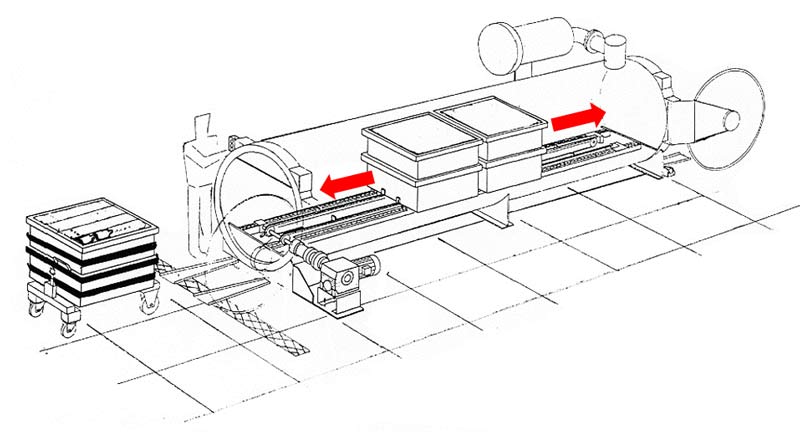

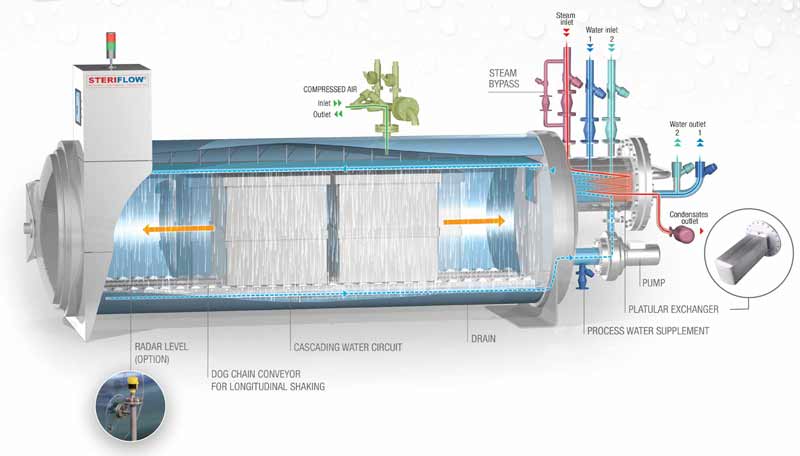

Dali Steriflow operates an agitation of the product in the same way than rotary retorts, for some applications, but for a smaller investment. A chain conveyor (with Dali customised solutions), used for baskets entry and exit, creates a longitudinal movement of 15 cm for 15 to 20 times per minute. Gentle motion operates in the length. Compared to Shaka, Dali is 10 times slower. It has been developed for sterilization of liquid or low viscous products.

Dali autoclave operating

With Dali Steriflow System, baskets of plastic milk jugs are moved back and forth horizontally at low-frequency through the internal handling chain. Bottles must have a head space ; the milk is agitated by a bubble moving inside the bottle. This agitation is enough to avoid skin formation and browning during sterilization.

This is similar to rotation.

The process used for this pasteurisation is ideal for sterilising your milk bottles, e. g. in plastic or glass packaging. You can also use a DALI autoclave for the sterilization of your sauces in your pocket and the sterilization of your drinks in cans. Find out more about sterilization of dairy products in our article : Chosing in-countainer pasteurization for dairy products

Technical specifications :

Standard sizes :

- 900 mm,

- 1300 mm, corresponding to maximum size of manually operable basket (476 cans 4/4 and a capacity from 1 to 9 baskets.

- 1450 mm,

- 1600 mm,

- 1800 mm,

- 2000 mm,

- Capacity from 2 to 9 baskets according to diameters.

Temperature :

The sterilization temperature (sterilization value or FO) is defined by the manufacturer and will depend on the initial contamination of the product and its bacteriological characteristics.

Benefits :

- We can achieve the same results as using the rotary process with liquid product. Dali is a less expensive and more flexible option as it is scalable to several package sizes in the same basket (unlike rotary where it is necessary to use different kind of baskets for each type of packaging).

- A small initial investment thus more affordable over the short term.

- We developed baskets specifically designed to this retort to provide an ease of use by operators.

- Low maintenance. Simple mechanics with a reduced number of parts.

- Packaging cooling is performed with sterile water.

Types of packaging or products :

- Dairy products, (do not caramelize thanks to low-frequency shaking),

- Liquid products,

- Sauces.

Accessories

-

DALI basket